Manufacturing of machinery

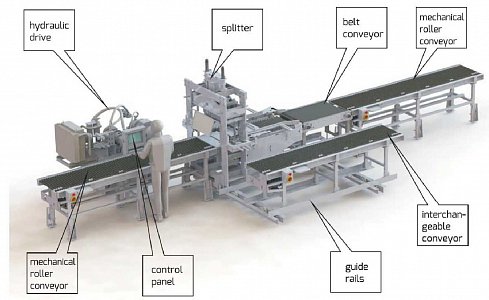

A proper functioning of the vibro-press block production line machines designed and manufactured by us (assembly bench, splitter, minivibro-press) is always verified on a long-term basis at our manufacturing plant, so we stand behind their quality. We will design and manufacture also other machines according to specific requirements.

We will be happy to assist you with a design and will be pleased to share our experience and knowledge with you. Thanks to many years of experience we will also be able to advice you how to improve your existing production results.

Our employees have experience in the field of hydraulics, pneumatics and electrical installations; with such in-house expertise and capabilities we are able to provide a comprehensive delivery of high quality machines.

Splitter

The machine is used to split vibro-pressed concrete monoblocks and stone. We also provide spare parts and other associated services, including e.g. spare splitting blades and their sharpening. This technological method of manufacturing produces a concrete block of which wall has a distinct plastic structure.

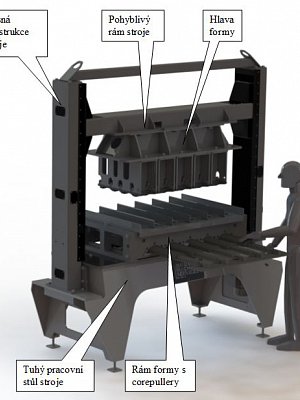

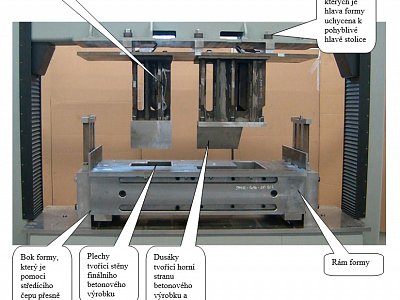

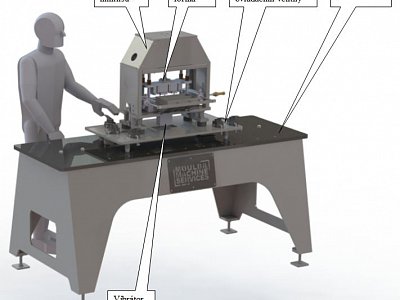

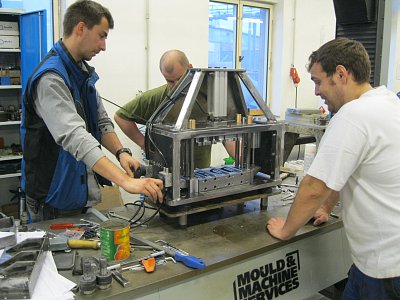

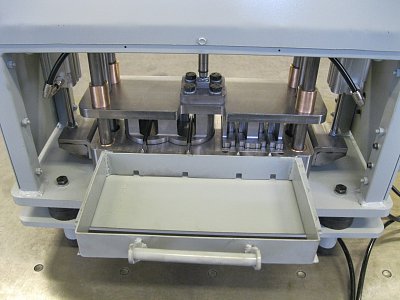

Assembly bench

The assembly bench is used for adjustment, assembly, maintenance and cleaning of vibro-press production moulds but also for example for the replacement of the wear parts of a mould A significant time savings can be achieved by using the assembly bench apart from reaching high accuracy in the course of the moulds adjustment, since the device clamps the head and the frame of the mould in exactly the same way it would be clamped in the press.

In practice, this machine is also used for cleaning moulds from concrete residues.

The moving part of the bench is driven by an electric motor. The speed is controlled by a frequency converter. The end positions are defined by limit sensors.

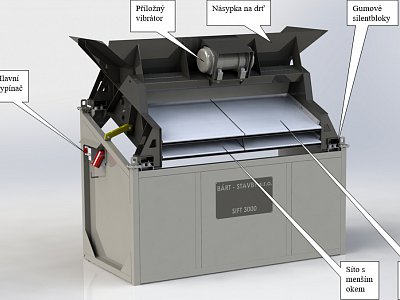

Minivibro-press

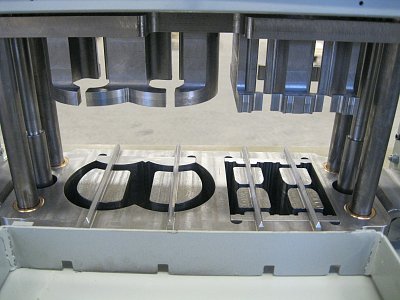

The machine used for the production of vibro-pressed miniblocks is primarily used for promotional marketing or display of textures and colours on small samples.

It enables the production of miniature concrete blocks. It is possible to create any shape of a concrete product, depending on the customer requirement. The mould in the press is replaceable and therefore it is possible to produce unlimited quantities of concrete products.

The produced vibro-pressed concrete blocks can be used as a realistic miniatures of the actual products, as gifts to potential customers, as an ideal tool for teaching employees, for simple demonstrations of the use or as colour samples.

The concrete blocks are not designed for real laboratory testing of vibro-pressed concrete blocks.

Machine drive: Compressed air (8 bar)

Machine control: Using manual valves

Other machinery, custom production

We are also able to design and manufacture machines and equipment other than those for vibro-pressed technology.

Our recent contracts included supply of conveyor systems, lift rails, attachments to moulds and individual parts for worn parts and units of vibration presses, bulk material sorters and other machinery.